The new Model Classic Plus square baler designed by Huaxi Technology, keeping classic but breakthrough, simple, and excellent, is newly launched.

Raw material cutting, bending, welding to assembly which are all equipped with intelligent equipment to ensure product quality and performance.

1.

Higher working efficiency

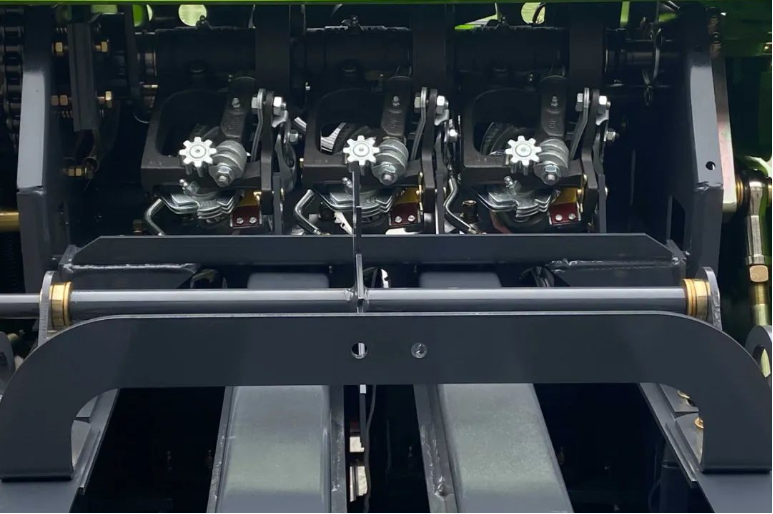

4 rows of pick-up teeth, “八”-shaped pitchfork, and a “horn”-shaped feeding inlet, lead to higher feeding efficiency; The flywheel is enlarged and heavier, the compression chamber is widened and enlarged, and the bale density and bale volume are greater. Equipped with five bundles of rope boxes on both sides, reduced the time cost of changing ropes, and the overall operating efficiency increased by more than 26%.

2.

Better looking and functional

The appearance adopts the streamlined hood of automobile technology, and the large frame adopts high-quality manganese steel, which increases the strength by 74%.

3.

More stable performance

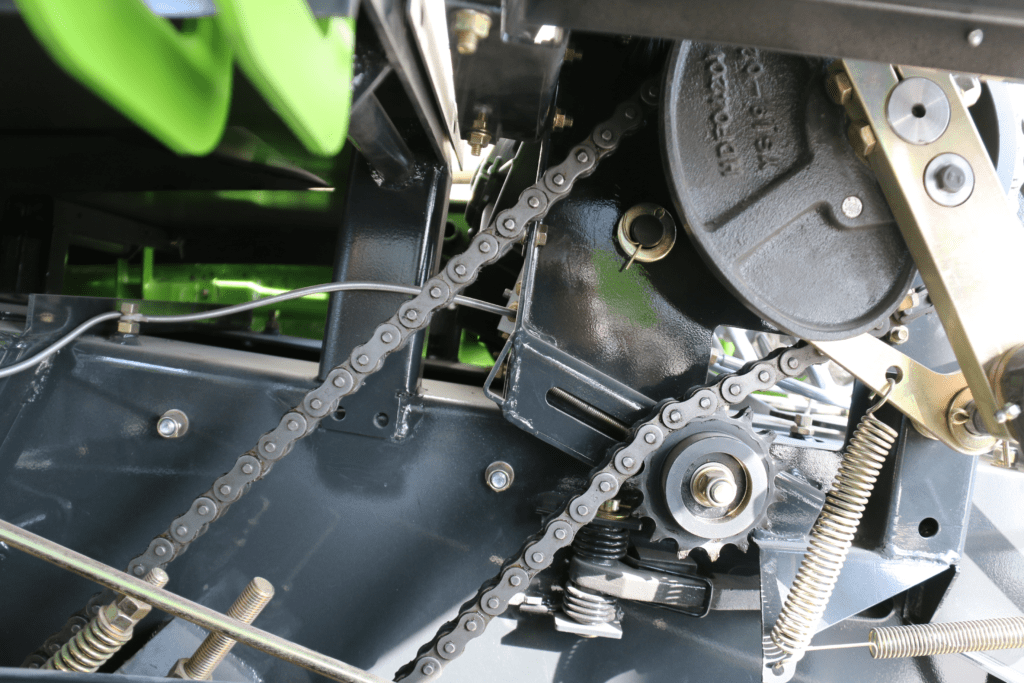

Three sets of Rasberg RS6003 imported from Germany strengthen the D-type knotter, increase the size of fan, and improve the working environment of the knotter. The service life can reach 1 million times, and the knotting rate can reach more than 99%; And using 16A and 12A chains which can improve the tensile strength of the chain, also reduce adjustment; Using reinforced traction head, make it easy to turn, strong and durable.

4.

Wider scope of application

The transmission shaft adopts a split structure, with a bridge transmission box in the middle, this structure is more reasonable, and the operation is more convenient; The hollow auger is used, which is suitable for pasture, wheat, rice and other crop straw operations; The auger bottom plate adopts mesh type, which can remove dust, make the straw cleaner.

5.

Higher intelligence

The Beidou intelligent positioning system can realize remote positioning, display operation status and dynamic faults on real time, playback of operation tracks, and traceability of historical operation status.

[ninja_form id=’3′]